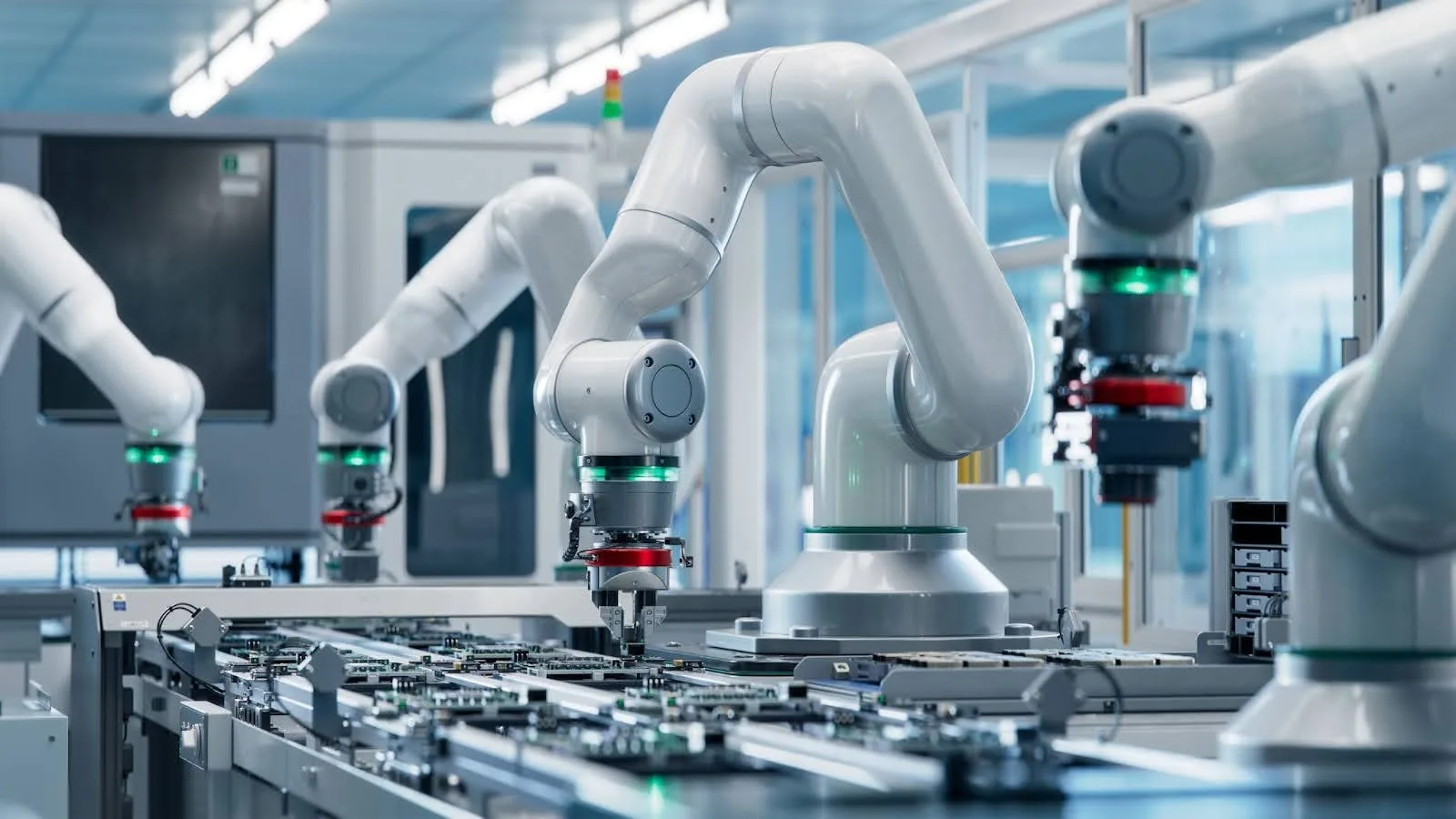

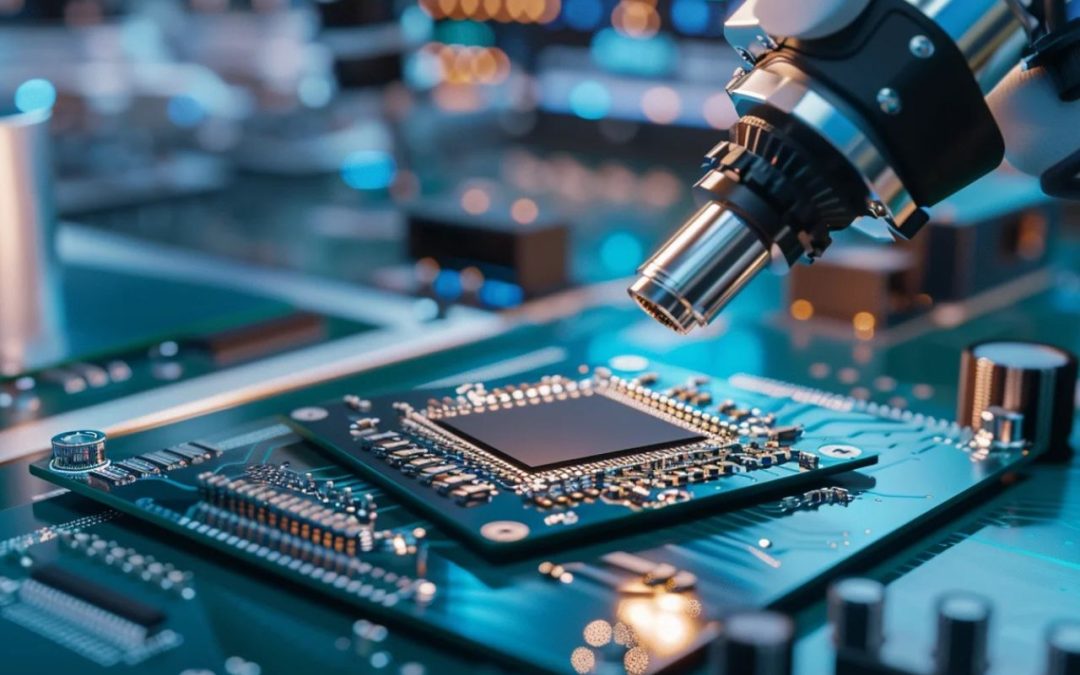

Mechanical Design & Development

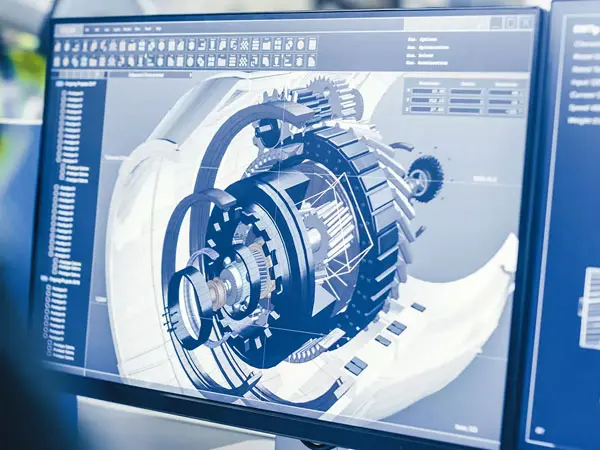

We translate your concepts and requirements into fully engineered solutions for components, assemblies, machines, and complex systems, focusing on functionality, reliability, manufacturability, and cost-effectiveness for new designs or modifications.

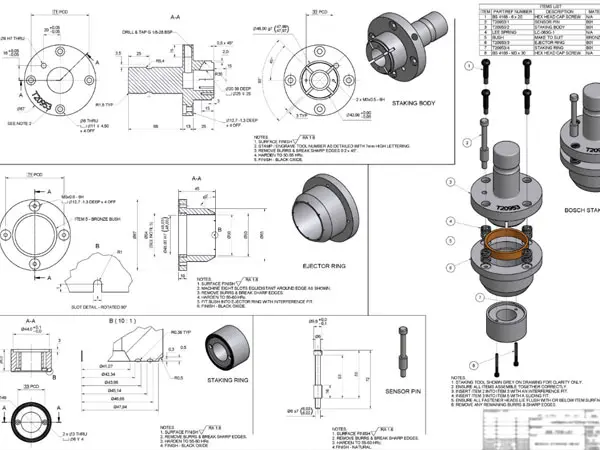

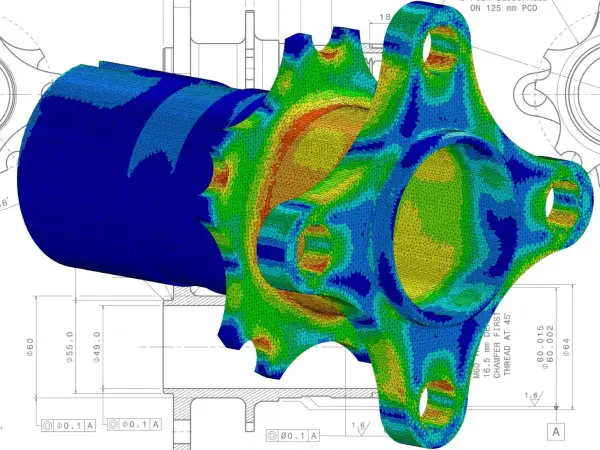

- What We Provide: Conceptual designs, feasibility studies, detailed 3D CAD models, engineering calculations, mechanism design, material/component selection, design reviews, and modification of existing designs.

- What You Get: Robust, efficient, and optimized mechanical solutions ready for analysis or manufacturing; reduced development risk and costs; expert guidance turning your ideas into tangible, functional designs.