Conceptual Design & Feasibility

Translating your initial ideas into viable sheet metal concepts.

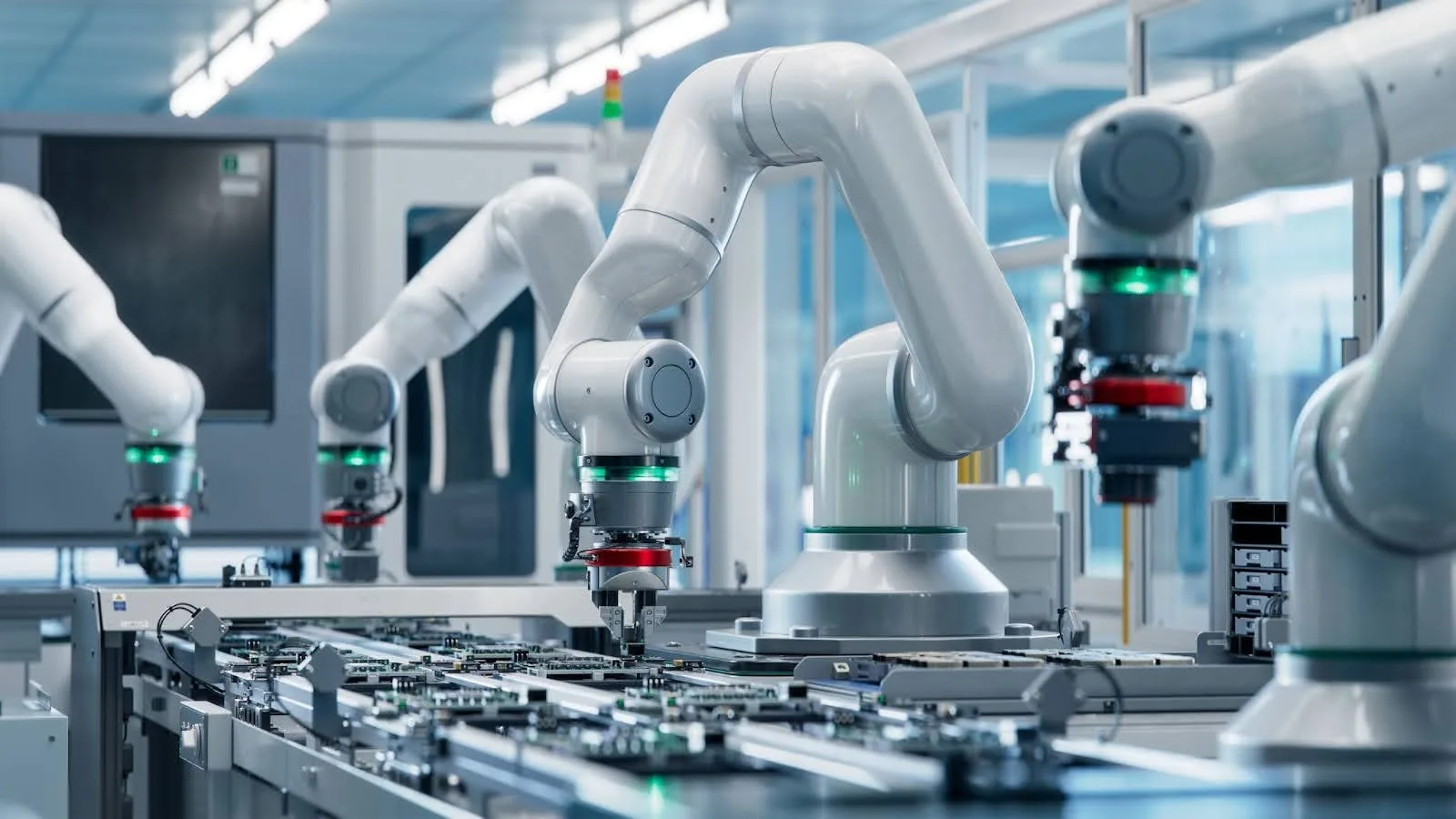

Struggling with sheet metal designs that drive up costs and delay production? TriAtrim Mechanical Designs delivers sheet metal solutions, tailored to your diverse needs. Whether you are a sheet metal contractor, fabricator, or an engineering firm, we help you build robust, manufacturable, and cost-effective components and assemblies, across industries like electronics, healthcare, and automotive.

Leveraging advanced CAD software, we provide detailed designs optimized for laser cutting, bending, and welding. Our process includes thorough Design for Manufacturability (DFM) analysis, precise flat pattern development, and rigorous prototyping, ensuring minimal material waste and maximum efficiency. We adhere to industry standards like ASME, ANSI, and TEMA, facilitating swift design approvals and ensuring assembly-friendly, production-efficient designs.

STEP 1

Understanding your project goals, technical needs, and constraints.

STEP 2

Developing concepts and detailed designs, incorporating your feedback.

STEP 3

Refining the design for optimal performance and manufacturability.

STEP 4

Providing complete design documentation (CAD models, drawings, flat patterns) ready for manufacturing.

TriAtrim has spent years developing its proprietary part analysis engine, which allows us to offer instant quotes and DFM feedback to our customers (in partnership with our sister company Komacut.com). This allows our engineers to rapidly iterate and turn around sheet metal quotations and prototypes, while offering unparalleled speed and quoting accuracy. Our state-of-the-art MES system allows us to feed real-time data back into our system, ensuring accurate pricing, planning and unmatched efficiency.

At TrimAtrim Mechanical Designs, our commitment to precision, innovation, and client satisfaction drives every sheet metal design project we undertake. With a team of experienced engineers and a focus on manufacturability, we deliver robust, cost-effective solutions tailored to your unique requirements.

I’m a professional specializing in design and manufacturing. Feel free to reach out with any questions or to discuss how I can help bring your ideas to life.